Practical Case of Mezzanine Floor Application in Tire Enterprises

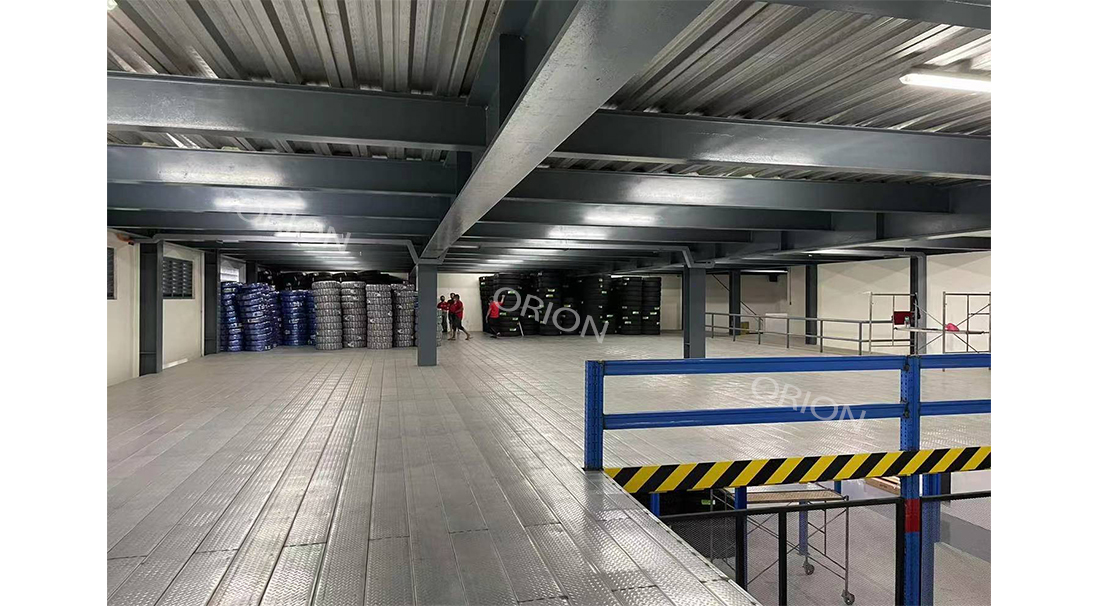

The customer is a local Philippine company specializing in high-quality tires, and providing one-stop auto maintenance services. With business expansion, the storage needs of its multiple service centers have grown significantly. The existing warehousing model can no longer meet development demands in terms of management efficiency, standardized goods storage, access safety, and convenience. To address these pain points, the client has ordered a batch of steel platforms from our company to optimize warehouse layout and improve the warehousing management of core products.

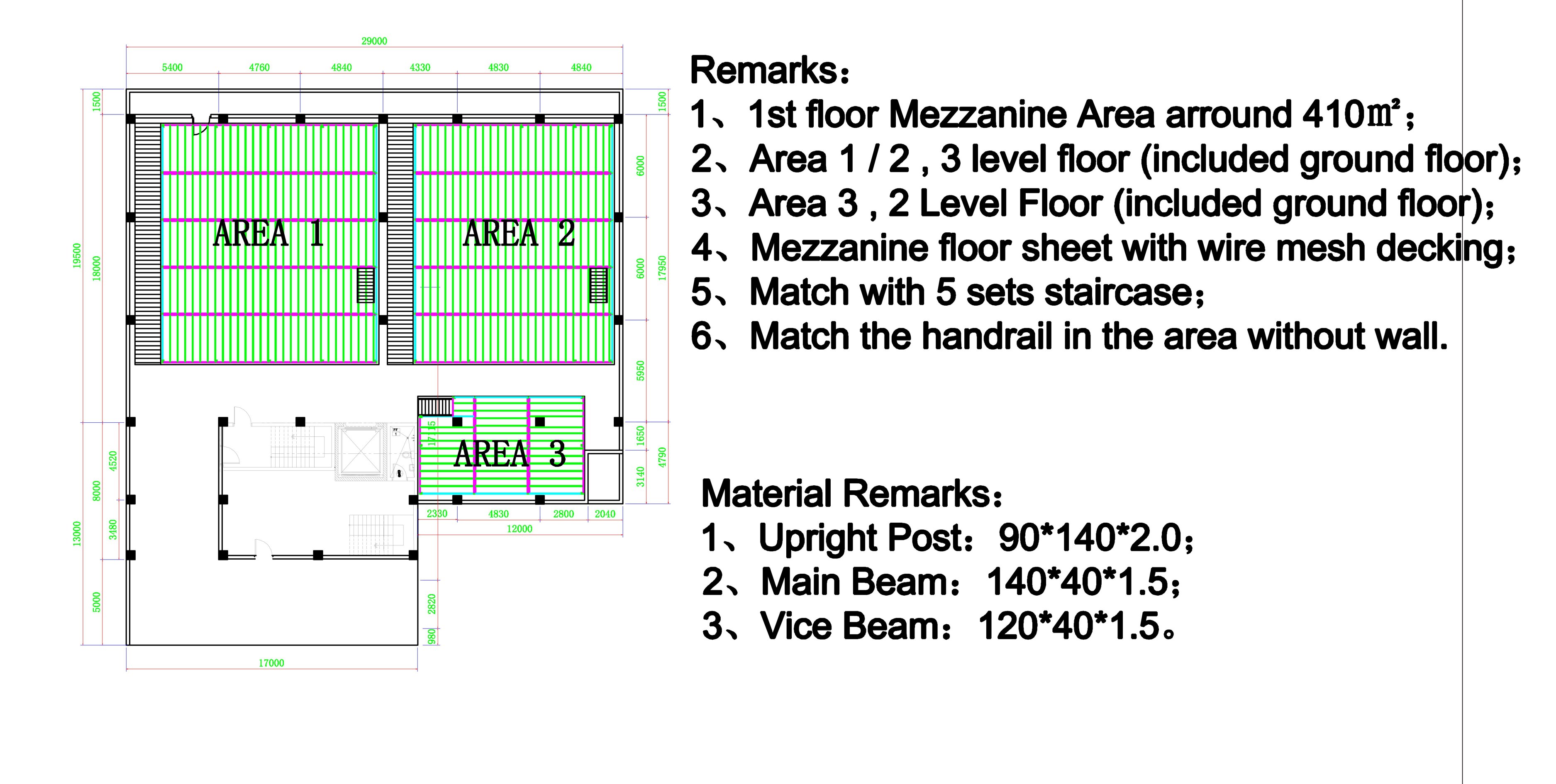

ORION’s baseline plan was as follows:

Space optimization: Maximize vertical space to adapt to the growing storage needs of tires and other goods, improving space utilization.

Standardized management: Designate exclusive zones on the mezzanine floor and standardize storage processes for clear classification and orderly arrangement.

Safety guarantee: 500kgs/㎡ load-bearing capacity, reinforced structural stability, and standard railings to ensure the safety of personnel and goods.

Efficiency improvement: Optimize stairs and access channels to shorten turnover paths, reducing costs and increasing efficiency.

| Floor Area | 410㎡ |

| Load-Bearing Capacity | 500kg/㎡ |

| Floor Height | 2040mm |

| Maximum Span | 3000mm |

| Handrail Height | 1200mm |

| Number of Stairs | 1 Sets |

| Stair Width | 1000mm |

| Floor Surface | Galvanized Steel Gusset |

Project Insight:

This solution focuses on the customer’s business development needs. By utilizing vertical space, it not only solves current inventory challenges but also builds a sustainable warehousing foundation in terms of safety, standardization, and efficiency.

The project fully demonstrates that customized warehousing solutions tailored to industry characteristics and regional environments can effectively connect core business operations with logistics support, becoming a key cornerstone for business expansion. It also reminds us that in cross-border services, we must accurately grasp the climate characteristics, industry pain points, and development stage of the target market, and deeply integrate product functions with the client’s actual needs to truly achieve the service goal of "cost reduction and efficiency improvement" and create unexpected value for clients.